AC DRIVES FEATURES

- 4 Control Method V/f, Slip Compensation, Sensor less Vector.

- Torque Boost - Manual / Automatic torque boost

- Effectively improve the power factor of input

- Wide voltage range design

- Excellent speed and torque performance

- A soft starter for motor

- Programmable ramp speeds

- Dynamic DC injection breaking

- Programmable voltage / frequency patterns (Allows wider selection of pump motors)

- Protected against dust by conformal coating

YOUR SUPPORT

Cooling, ventilation in HVACs climate control a VFD playing an important role. The room or Hall temperature is always measured by temperature controller and its feedback given to VFD to maintain a room temperature in a constant or some of exact cooling condition.

To control flow & air volume of the fans, the most scientific way is to adopt a variable frequency drive to avoid unwanted initial currents and spikes.

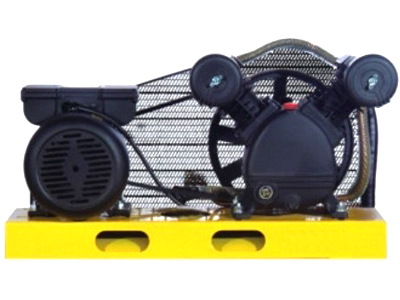

AIR COMPRESSORS FROM TEXTRO

In compressors, Sensors are used to detect pressure, and it can be fed into the drive control module to accurately determine the optimal output frequency and motor speed. If a given variable changes, the drive can be set-up to automatically adapt the frequency, altering the speed of the motor. Once the sensors indicate that the desired state has been achieved, the drive can then normalize its frequency.

Production of compressed air always follows the demand it can monitor by sensors. So we can get stable pressure ratio.

CNC MACHINE-VTL/HTL

During machining process, usually there is a requirement for a different rotation speed of main spindle, operation staff controls separation and integration of clutch via multiple positions of handle combination, gets multiple combination of gear to obtain multiple speeds, operation is inconvenience and maintenance is large, practices show that the fault rate of electromagnetic clutch usingto adjust speed is high.

The mechanical parts of clutch gear box reductions are removed by the implementation of VFD technique. Still the need of all different speed can achieve with better accuracy. Also provides smooth operation, results good machining output in performance.

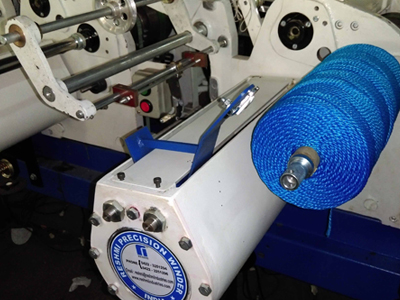

YARN WINDING

The yarn winding machine motor is operated at constant speed irrespective of the requirement. As the speed is varied as per the spindle speed requirement by optimizing the motor speed will reduce the power consumption per kg of yarn processed. Considering the above facts and for reducing electricity consumption in the yarn machines, it is suggested to install VFD for quality winded yarns.

Reduction in production cost and maintenance cost due to frequent failures of belts, bearings, and yarn breakages.

KNITTING MACHINE

The circular knitting machine requires the motor to forbid the reversal and rotation phenomena, otherwise the needle of the needle bed will be bent and even broken..

First is the inching operation, with the frequency of 5-6Hz. Second is the normal high-speed weaving operation, with the maximum frequency reaching 50Hz attained by means of VFD.

VFD - SOFT STARTER

Our TEXTRO VFD's can save a lot of energy. And they are good at reducing peak energy demand or reducing power when not required. They offer fully adjustable speed (pumps, conveyors, and fans) and can control starting, stopping, and acceleration. They have dynamic torque control and they provide smooth motion for applications such as textile and loom industries.

They can maintain speed of equipment, making them ideal for manufacturing equipment and industrial equipment such as mixers, grinders, and crushers.